The first wave of the fourth industrial revolution, a.k.a. Industry 4.0, has officially arrived. By 2028, the global Industry 4.0 market is expected to reach $279.75 billion (USD).[i] Growth is being driven by the rapid adoption of IIoT, AI, robotics, edge computing, and blockchain and is affecting sectors across the industry spectrum, including manufacturing, pharmaceutical, transportation & logistics, chemical, and food and beverage.i.

The enthusiasm around Industry 4.0 is not surprising. The anticipated benefits from widespread deployment of automated mobile robots/guided vehicles, artificial intelligence, digital twining and next-generation analytics are very attractive. But before these disruptive technologies can go mainstream, there are some important details to work out, the most important of which is the network infrastructure needed to support them.

Opportunities and Obstacles of Industry 4.0

Whereas Industry 3.0 was defined by the widespread adoption of digital technologies like computers and process logic controllers, Industry 4.0 is all about fusing digital, physical and virtual resources, including AI, robotics, IoT, 3D printing, quantum computing, and other technologies. This hyperconnected, cyber-physical environment is expected to drive autonomous and real-time analytics and decision making that can radically improve outcomes and efficiencies throughout the supply chain and beyond.

For companies that get it right, the results are impressive—production efficiency gains of 15% to 20%, as well as improved production flexibility and quality—versus the average 2% to 4% returns from classic continuous improvement methods.[ii]

Industry 4.0 is all about fusing digital, physical and virtual resources, including AI, robotics, IoT, 3D printing, quantum computing, and other technologies.

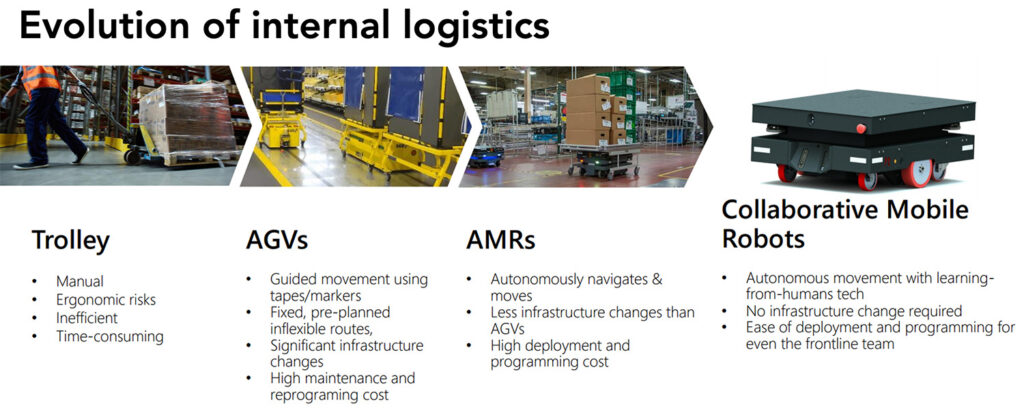

Among the major differentiators of Industry 4.0 will be the widespread deployment of automated mobile robots (AMRs), a foundational component of the fully automated warehouse. AMRs are quickly finding their way into virtually every corner of the industrial enterprise, with one of the fastest applications being material transport.

On-going development of AMRs for material handling enables companies to minimize the safety risks to employees and re-allocate those workers to higher-value tasks. This is often known as “the automation of the 4Ds: dull, dirty, dangerous and difficult tasks,” enabled by advances in computer vision, machine learning and AI. These advances are increasing warehouse robots’ capabilities, with the latest models able to plan their own best routes and picking sequences while navigating autonomously in complex environments.As a result, AMRs are being deployed in a wide variety of use cases, including pick and place, dispensing, packing, assembly, machine tending, palletizing and part transfer tasks to name a few.

Another AMR use case quickly gaining momentum is the use of robots for facility security. In addition to security cameras, motion detectors and access control systems, manufacturing operations are now integrating one or more AMRs that patrol the premises, inside and out. More than detecting hazards or anomalies, these specialized AMRs can also interact with employees, enabling them to report a concern or get basic information in real time. Security AMRs use algorithms and artificial intelligence systems to analyze and process the information gathered, making informed decisions and issuing alerts in the event of threat detection.

Collaborative automation will be key to realizing the potential of automated robotics as it transforms AMRs into collaborative robots (cobots). Fueled by robotic advancements like state-of-the-art sensors, machine learning and AI, collaborative automation allows cobots to perceive their surroundings, understand human intentions, and adapt their behavior accordingly. Meanwhile, integrated safety features such as force sensors and collision avoidance systems help ensure that humans can share the same physical environment as co-bots.

While benefits like these have been anticipated and highlighted for several years, the path to realizing those benefits remains a bit more elusive—beginning with the network infrastructure. When asked to identify their top roadblocks to implementing Industry 4.0, executives from across the globe pointed to network-related concerns:[iii]

- Networking Capabilities and the Operating Environment

- Data Silos and Data Availability

- Cybersecurity and Cyber Threats

These concerns echo what CIOs and their network planning and management teams have known for some time. The next big jump in industrial networking will require addressing some of the most difficult challenges currently being faced, but on a much larger scale:

- Hyperconnected, supporting massive deployments of IIoT devices, sensors, AMRs, AGVs, etc.

- Edge-based, providing access and compute power where data is generated and consumed

- Highly secure, as hyperconnected networks become a favorite target of bad actors

- Highly reliable, able to maintain carrier-grade mobile connectivity, 24/7/365

- Ultra-low latency, to support real-time data analytics and decision making

Meeting these requirements and making the leap from Industry 3.0 to Industry 4.0 will mean rethinking existing network topologies and technologies. An all-digital infrastructure, along with new operational processes will be the ante for those looking to upgrade to the factory of the future.

Traditional Wi-Fi networks may not offer the reliability and scalability required for advanced robotics, especially for mobile robots that traverse vast areas. This can be especially problematic as robots move from indoor to outdoor areas and vice-versa. This is where next-generation enterprise connectivity solutions, such as Private LTE/5G, can make a significant difference. (For more on this subject, check out Why Robotic Solutions Need Reliable Connectivity.)

The Role of Private Network Connectivity

IT-based wireless solutions like Wi-Fi can be adapted to industrial applications but often impose limitations regarding reliability, security, predictable performance, multi-user capacity and mobility. For example, Wi-Fi signals do not propagate well in many industrial environments where building structures cause interference. Therefore, it is unable to adequately support the mobile requirements of automated robots; nor can it support the reliable low power requirements of IoT devices or the high density of sensors, devices, robots, workers and vehicles that operate in the typical manufacturing plant.

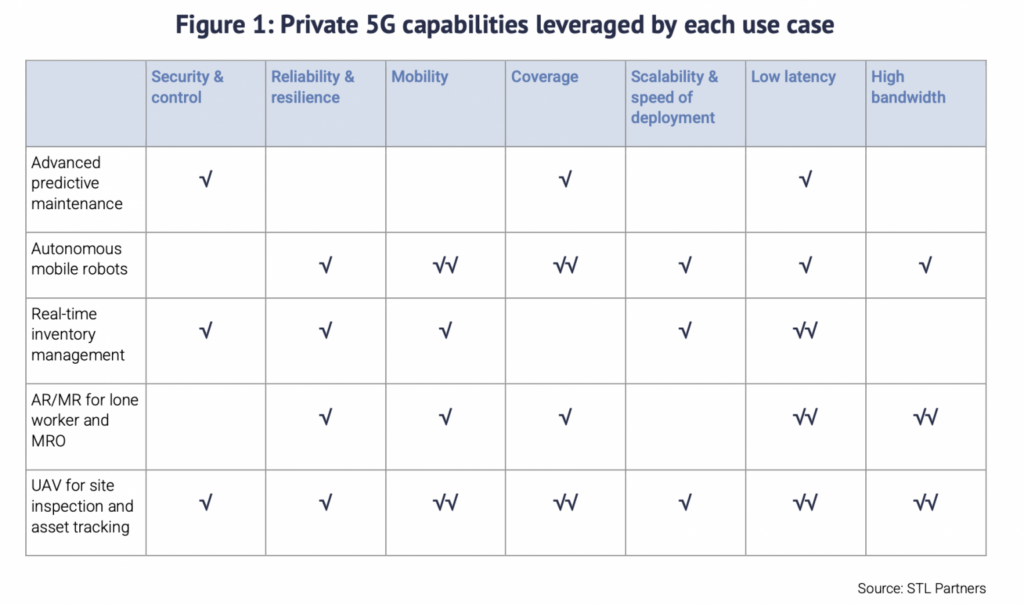

Conversely, private LTE/5G give industry networks the flexibility and performance to support the connectivity and security needs for a highly diverse and hyperconnected Industry 4.0 eco-system. For starters, private LTE and 5G enable organizations to own and control their networks, enabling them to optimize performance for their specific use cases and determine the authorization and prioritization of the traffic.

Private LTE/5G also enables higher reliability and broader connectivity and mobility versus Wi-Fi. So, AMRs, AGVs, embedded IOT sensors and other mobile automated equipment can operate unimpeded across robust industrial environments. They also support high uplink speeds, excellent quality of service (QoS), sub-millisecond latency and multiple SLAs for network slicing.

On the operations and management side, private mobile networks enable IT teams to dynamically create, configure, and scale network resources to meet the company’s specific operational technology needs.

One of the most important advantages of private networks is the enhanced security it offers. For starters, data consumed and created remains on-premise without having to be routed back to an operator’s network where it is vulnerable to exposure. Support for a SIM-based security layer will also further mitigate cybersecurity and cyber threat vulnerabilities at the device level and for local edge processing.

Prepare for Industry 4.0 with Trilogy NextGen

The fusion of robotics and advanced connectivity will reshape our world and enhance the lives of millions, making the impossible possible. At Trilogy NextGen, we’re leading the way forward. Every day, we partner with our industrial customers, to build, deploy and manage private networks that enable them to digitize and secure their business processes and realize the transformative value of Industry 4.0.

It’s time to embrace the extraordinary potential of robotics and unlock a future where humans and robots collaborate in harmony. By exploring the potential of private LTE/5G in robotics, AI and analytics, we can ensure a more efficient, safer, and opportunity-rich world for everyone.

Contact us today to learn more about how Trilogy NextGen can help you prepare your facilities and operations to transition to Industry 4.0.

[i] Top 10 Leading Companies Offering Industry 4.0 Solutions; Emergen Research, market study; April 20, 2023

[ii] Industry 4.0: Getting Digital Manufacturing Right; Bain & Company, blog; August 30, 2019

[iii] Overcoming Roadblocks to Industry 4.0; Nokia and Parks & Associates, research report; May 2022